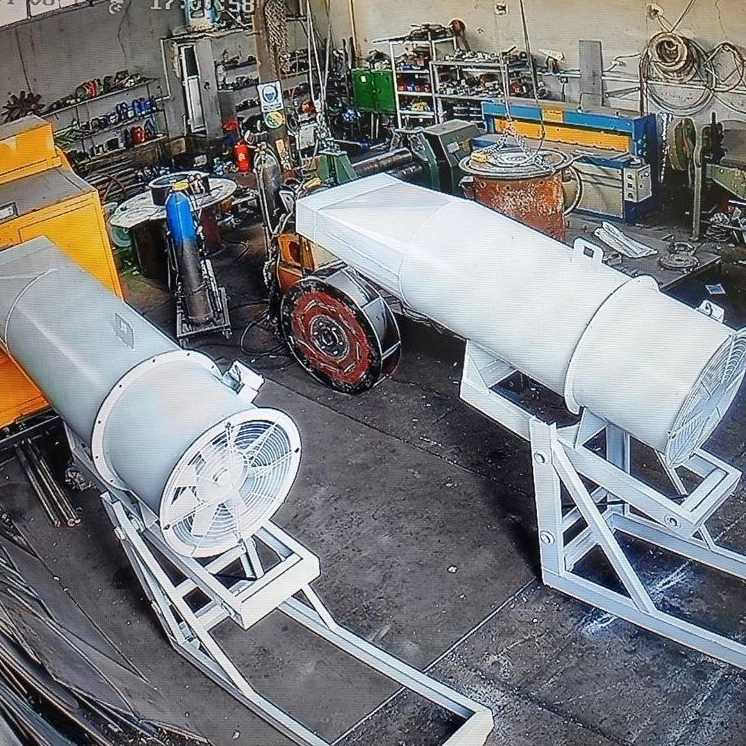

Kaveh Koling industrial jet fan

Wall cooling of thermal furnaces with high pressure and controlled flow technology

Introduction

Jet Fan is one of the most important ventilation and cooling units in thermal industrial units. Kaveh Cooling's wind equipment, focusing on the exclusive design of high pressure and axial flow systems, has been able to develop a model of industrial jet fans that, in addition to airing closed environments, also have the ability to cool the walls of induction and thermal furnaces.

The technical structure of the Kaveh cooling fan jet

1. Body and housing:

2. Axial propeller (Impeller):

Diameter from 500 to 960 mm, made of titanium aluminum alloy to maintain strength at high speeds, angle of attack 30° to 38°.

3. Electric motor:

4. Power transmission axis and bearings:

Design with Dynamic Balancing system and SKF bearings resistant to 180°C.

5. Intelligent launch and control system:

Equipped with Kaveh Cooling KS-Drive inverters with the ability to continuously control the output flow of cooling air (Variable Air Volume).

Furnace wall cooling mechanism

In heat treatment and melting of metals, the temperature of the surface of the furnace wall sometimes increases up to 900°C. By creating an air flow at a speed of 22 m/s and a static pressure of 750 Pa, the Kaveh Cooling jet fans cause:

- Decreasing the temperature of the furnace surface to ≤180°C in a radius of 2.5m within 3 minutes.

- Preventing the failure of the refractory layer (Refractory Layer) and increasing the life of the refractory brick up to 2 times.

- Thermal line stability in the working range of 80-300°C for continuous production process.

Standards and tests

- Design according to EN 12101‑3 (Fan for Smoke and Heat Control Systems).

- Thermal performance test according to ISO 5801 / ISIRI 9766 at a flow rate of 18000m³/h.

- Approved vibration less than 4.5mm/s according to ISO 10816‑3.

- Structural resistance to direct fire up to 45 minutes (Structural Fire Resistance Test).

Advantages and industrial strengths

- Reduce energy consumption up to 30% compared to centrifugal fans

- Ability to install on the ceiling and industrial facades with heat-resistant bases

- Compatibility with PLC and industrial BMS systems

- Modular design suitable for quick repairs

Applications

- Cooling the walls of steel and aluminum melting furnaces

- Ventilating thermal tunnels and furnace operation rooms

- Creating uniform air flow in bending and forging lines

- Combustion room temperature control in power plant systems