What is a centrifugal fan?

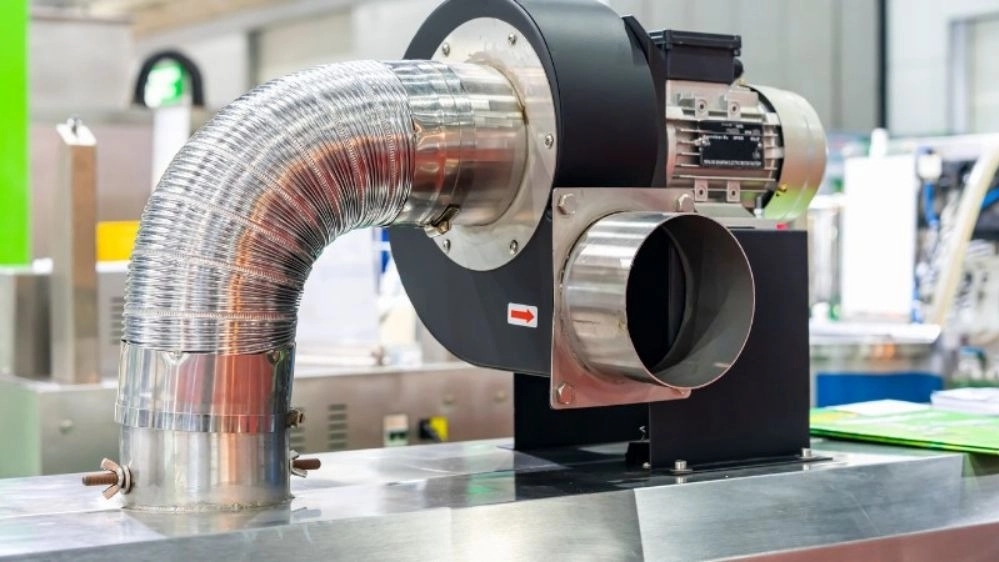

Centrifugal fan is used in ventilation and circulation and transfer of air from centrifugal force. This fan is widely used in places that have impure air with dust and dirt, as well as environments where the temperature increases due to industrial activities. One of the most important features of this type of fan is the ability to deal with high static pressure drop in ducting systems.

The speed of this ventilation system is measured based on revolutions per minute, and in normal conditions, its lowest speed is 78 revolutions per minute and increases up to 40,000 revolutions per minute. Of course, nowadays, centrifugal ventilation systems with higher speed are also produced and supplied, which are completely suitable for harsh industrial environments.

What are the characteristics of a centrifugal fan?

Centrifugal fan has various features, the most important and familiar of which are:

1. The method of air discharge in a centrifugal fan is in the direction perpendicular to the rotation of the propeller axis. The most use of this centrifugal aerator is in channel systems with high pressure.

2. This fan is suitable for use in places that have dirty air and contain impurities or even high temperature places.

3. It has the ability to deal with high static pressure drop in packages and channeling systems

4. The normal speed of this centrifugal fan under normal conditions starts from a minimum of 78 rpm and continues up to a maximum of 40,000 rpm.

5. Suitable for moving gases, air and vapors in ventilation systems

6. Dealing with the pressure drop of different systems

7. The ability to achieve air density at high scales

Centrifugal ventilator components

Centrifugal ventilators have common components in any type and size and for any environment that is produced. In other words, in the construction of all these parts, common parts are used and in this way a harmony will be created between them. In general, the main and most important parts of a centrifugal fan are:

• Fan driver

• Fan impeller drive shaft

• Butterfly

• Housing

• Air outlet and air inlet

The mentioned parts are not the only parts of the centrifugal fan, and this device also has sub-parts, the most important of which are:

• Bearing

• Propeller lock device

• Shaft sheet

• Bearing

• Fan discharge chamber

• Fan valve compartment

• And…

Centrifugal fan applications

The most important and familiar applications of centrifugal fan in the industry are:

• Mines

• Industrial kitchens

• Industrial furnaces

• Industrial laboratories

• Automobile manufacturing

• Industrial factories

• Production sheds

• Workshops

• Tunnels

• And…

Residential and urban applications of centrifugal fan

Centrifugal ventilation is not only used in industrial affairs, and its most important residential and urban applications are:

• Hotel

• Parking

• Car wash

• Office buildings

• Meeting halls

• Hospital

• Laboratories

• Kitchen hoods

• Elevator

• And…

Types of centrifugal fans

Fan Forward:

This type of ventilator has a low rotation speed and reduces the sound to a great extent. Other features of this type of fan include its small size and lower efficiency compared to other fans. The curvature of the propeller blade in this fan is forward and it is easily recognized by the appearance and shape of the propeller.< /p>

Backward fan:

The propeller of this type of fan has blades that move in a curved direction while rotating around the propeller. Strictly speaking, it can be said that there are three shapes of flat, curved and airfoil blades in the backward fan. Flat blades are very strong and curved blades are efficient.

It is good to know that the most important difference between forward and backward fans is their efficiency. Backward fans are often used in places with long ducting and high pressure drop. Of course, these ventilators are also used in places with high humidity and high temperature.

Airfoil fan:

This type of fan has the most efficiency among all types of centrifugal fans, and if you plan to use your fan in environments where the air is clean, this fan is the best and most suitable option. The airfoil fan can move at a very high speed and even its speed is twice that of the forward fan.

radial fan:

Radial fan does not create much air flow, but the air pressure in it is high, and this makes this fan usable in industrial environments, environments where there is a lot of dust.

What are the advantages of using a centrifugal fan?

Using a centrifugal fan brings various advantages, so if you are looking to know what are the advantages of using a centrifugal fan, we have discussed the most important ones:

• Very high durability and resistance

• High compatibility with ambient air and working in dry, normal and humid weather

• Design and production in different sizes and use in any situation

• Centrifugal fan by creating constant air flow allows the generated energy to be static efficiency up to 84% and this level of efficiency can be useful for maintaining larger air systems.